Rudder, Rudder Post and Rudder Tube Problems and Repair

Replacing my Hurely 22 rudder tube - an essay

Hurley 20 Rudder Repairs

Darren has sent us a sequence of pictures showing the repair of his rudder and rudder post He says:

"You

can see how little of the original rudder post remained, the cut from

the narrow grinder blade, the rudder split in two, the rust inside from

some water ingression (although not as bad as some others have seen).

You can also see the interesting trick of Second Wind standing on her

tip toes to make enough room to get the rudder back in (I tried to dig

a hole, but just short of the required depth there was a small boulder).

I also added a zinc (turned down on the lathe) to do double duty to

protect from further corrosion and to act as a spacer to remove play

in the rudder. After the photo shown I had to bring the zinc back to

the lathe one more time to shape it so it fit better against the hull.

On the topside of the rudder post I added a delrin disc which is thick

enough to pull the zinc right up against the hull which removes all

the vertical play in the rudder."

|

|

|

|

Old rudder |

Close-up of split rudder |

Material rusted away from rudder post |

Split rudder around perimeter |

|

|

|

Rudder split in half and post removed |

Rust in rudder blade |

Lots of clamps |

|

|

|

Zinc collar |

On her toes |

New rudder in place |

New Hurley 24 Rudder

These pictures show a new Hurley 24/70 rudder being fitted by Maurice Huffy of Blaxton Boats

|

|

Hurley 22 Rudder Problems

Hurley 22 leaking rudder tube. Leaking rudder tubes and glands are an issue on Hurley 22 yachts. The Hurley-built 22 had a rudder tube of galvanised steel that would rust and fail with foul consequences. This is a common problem and the weakest link in otherwise sound boats.

You need to cut the tube out with an angle grinder from inside of the vessel, crawling under the cockpit and squeezing past the cockpit drains. This is not a pleasant job but will be helped by creating an inspection hatch with cover at the aft end of the cockpit sole. The tube should be replaced by an item of stainless steel, cut to length and threaded at each end to allow for a skin fitting nuts to secure. These skin fittings should be reamed out to create a rudderpost bush at top and bottom.

However, your friend might have a rudderpost with stuffing box gland? These are easy to stop leaking just by re-packing with cotton wadding and grease.

Or you could use the easier method that later Hurley 22s had. That is a PVC hose between two bronze skin fittings that are reamed out to 1" to act as bushes. The hoses are held in place by hose clips.

|

|

|

|

|

Rusty rudder tube - Hurley 22 |

Rusty rudder tube - Hurley 22 |

Hurley 22 - weak GRP in rudder area - from Harmut Dietrich |

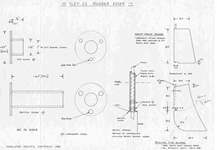

Hurley 22 rudder drawing |

|

|

|

|

Hurley 22. Rusty rudder tube inside boat - normal |

Hurley 22 - rusty rudder tube |

Hurley 22 rudder tube modified with PVC hose |

|

|

|

|

Hurley 22 rudder tube modified with PVC hose |

Hurley 22 - rudder tube access hatch |

|

Hurley 22 Replacement Rudder Tube

Work carried out for Ben Hillwood-Harris by Ryan at The Metal Clinic Ltd.

Rudder Tube:316 grade stainless steel

Dimensions:Tube Length 840mm

-

To allow approx 10mm at either end for external s/s nut skin fittings

External

Diameter 42.2mm with 4.5mm wall thickness

Internal Diameter (with nylon bush) 28mm

-

(plus due to the nature of my rudder stock, a nylon bush with an internal diameter of 25mm was required at the base of the rudder tube)

Length of thread along tube (both ends) 100mm

4 s/s nut (as skin fittings)

4 s/s washers (as skin fittings)

Description

My rudder tube was the original (I think) and was completely rusted through; Nick Vass who surveyed the boat was surprised it hadn't sunk. It appeared that somebody in the past had made some repairs, as there was some epoxy/glass fibre seal internally at the hull end of the tube. I managed (through an inspection hatch) to break the tube and release the top half on the old tube through the rudder tube hole in the deck. The bottom half wasn't half as easy. I had to carefully grind the old section of tube and skin fitting nut (bronze) but eventually it came free, with out damage to the hull!

I took the whole rudder and stock to the fabricator to ensure that the fit was good. Ryan turned the job around fairly quickly, a week or so once he had sourced the tube.

Because my rudderstock had various 'collars' (i.e. its diameter wasn't uniform ranging from 25mm - 28mm approx) Ryan had to split the bush into two parts, the bottom (hull end) was also split into along its length to allow fitting as the rudder and stock was refitted. Click here to see a drawing.

Replacement Rudder Tube - Bilge Keel Hurley 22

Gary describes how he replaced his rudder tube.

When

I bought my Hurley 22 bilge keel,the owner told me she had recently

had a rudder repair after a brief grounding incident and that there

had been some minor fibreglass work to the bottom edge. Ihad a quick

look and sure enough there was some evidence of recent repair, with

that Ioverlooked the rudder stock and tube thinking, wrongly now, that

it would have been all in good order. I suppose that's the danger of

buying a boat full of enthusiasm and trust, but with little knowledge.

After I paid up and on my first real poke about, Itook a torch and inspected

the aft end through the rear hatch. The rudder tube was a galvanised

pipe of 2 inch diameter, fixed at the top and bottom with steel nuts

and an oak washer to protect the hull at the bottom end. The tube appeared

to be in good shape apart from some rust at the bottom end where the

water had probably seeped through the top nut and steel washer, which

were looose, resulting in the whole rudder assembly slopping about in

its seat. I crawled up the rear compartment, pretty tight, smelly and

itchy on the arms, so wear some long sleeved overalls, and got a real

good look at the tube. Sadly after a prod with a screwdriver the flakes

of rust peeled away and there appeared to be serious thinning of the

tube around the bottom nut, so Idecided to replace it before she went

back in the water. The next time I crawled into the hole, I took a hacksaw,

hammer and chisel. I managed to cut the edges off two sides of the nut

and with a bit of persuasion from the hammer and chisel the nut came

away and the tube dropped onto the rudder. The top nut was cut off in

the same fashion. The back end of the boat was lifted with the yard

crane and, just before the bow touched the yard, the rudder came out.

After talking with Nick Vass I decided to replace the tube with a stainless

steel pipe and nuts. I tried a few boat yards, engineers and chandlers

but the cost was fairly high, so I went to a local engineer in town.

Again he said he would thread a pipe and fabricate some nuts but the

cost was increasing, he suggested trying a company who made equipment

for milking machines and transport and after a quick phone-cal,l they

said they had the pipes and nuts in stock and all Ineeded to do was

give them the length and they would thread it as required. They were

brilliant, even said they would post it to me but I went down to Salford

and picked it up. They even turned me a brass collar on the lathe whilst

I was there, to prevent the rudder stock moving sideways in the tube.

The cost for all this was £27! I was amazed. The replacement was

the reverse and the tube was firmly secured with the new nuts and reassembled.

Hurley 24 Rudder Post Replacement

|

|

|

|

Old, rusty, galvanised rudder tube |

New, stainless-steel rudder tube |

||

See also the FAQs page